What Is Extended Producer Responsibility (EPR) and Why Does It Matter to UK Food Businesses?

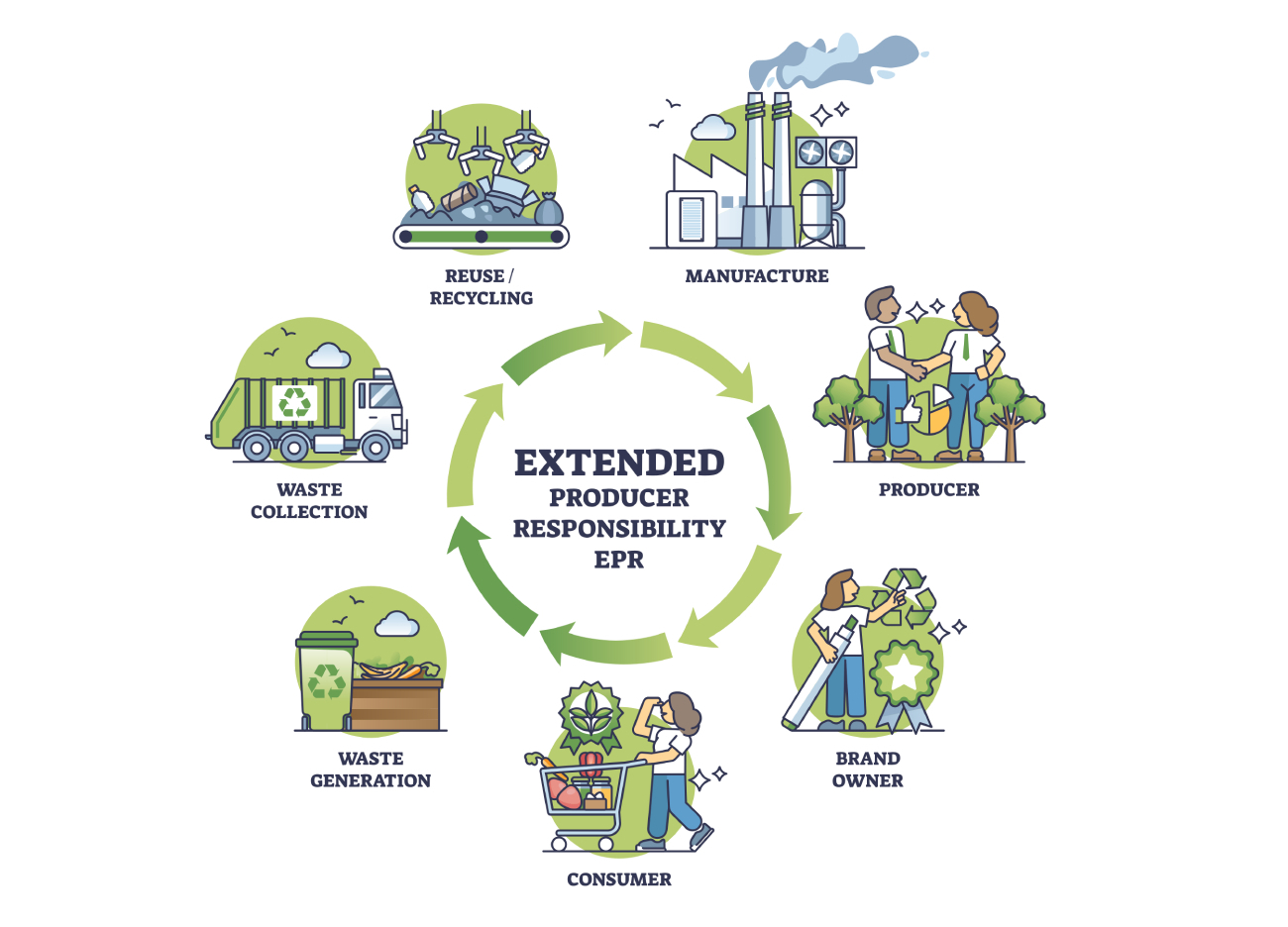

Packaging has always played a role in sustainability discussions, but Extended Producer Responsibility has moved it firmly into the spotlight. As EPR regulations take effect across the UK, food businesses are being asked to take greater ownership of what happens to packaging once it becomes waste. This shift is prompting manufacturers and retailers to reassess packaging formats, materials, and components through both a compliance and commercial lens.

Extended Producer Responsibility places the cost of managing packaging waste on the businesses that place it on the market. This includes the cost of collection, sorting, recycling, and disposal. For food manufacturers, bakeries, and retailers, EPR is not simply an administrative requirement. It has direct implications for packaging design, long-term costs, and sustainability performance.

Who Is Required to Comply With UK EPR Regulations?

UK EPR applies to organisations that supply packaged goods to the UK market, including brand owners, producers, importers, and retailers. Businesses are required to report detailed information on the type and volume of packaging they place on the market and, in many cases, will be required to pay fees linked to that packaging.

For food businesses, this means that packaging components previously treated as minor details are now subject to closer scrutiny. Films, labels, closures, and secondary packaging all contribute to overall reporting obligations and future fee structures.

How Does Packaging Design Affect EPR Costs and Reporting?

One of the core principles of EPR is that packaging should be easier to collect, sort, and recycle. Packaging that performs poorly in these areas is expected to attract higher costs over time.

As a result, packaging design decisions increasingly influence both compliance effort and financial exposure. Material choice, weight, and structural complexity all play a role. Even relatively small packaging elements can affect how a pack is classified and how easily it can be recycled. This has led many food manufacturers to reassess packaging systems as a whole, rather than focusing only on primary materials.

What Does EPR Mean for Flexible Packaging and Sealing Solutions?

Flexible packaging is widely used across the food and bakery sector due to its efficiency and material savings. However, multi-material structures and additional components can complicate recycling under EPR.

Sealing and closure solutions are part of this equation. Packaging designs that rely on multiple materials or rigid components can increase complexity, while lightweight, integrated solutions can help maintain functionality with lower material impact. Tape-based sealing and resealable closures offer one way to deliver performance benefits such as freshness retention and reclosure without significantly increasing material use. When designed to work with flexible films, these solutions can support packaging strategies that align more closely with EPR objectives.

How Are Food Manufacturers and Bakeries Responding to EPR?

EPR is driving a shift in how packaging decisions are made across the food sector. Rather than reacting to regulations in isolation, many businesses are taking a more strategic approach, reviewing how packaging performs across the full lifecycle. For bakeries, this often includes high-volume products such as bread, where packaging choices are multiplied at scale. Improving packaging performance after purchase can help reduce food waste, while optimising materials can help manage future EPR-related costs.

Packaging suppliers are increasingly involved in these discussions, supporting manufacturers with solutions that balance efficiency, functionality, and regulatory alignment.

What Role Do Packaging Partners Play in EPR Readiness?

Meeting EPR requirements often requires collaboration beyond a manufacturer’s own operations. Packaging partners are expected to contribute insight into material efficiency, recyclability considerations, and evolving regulatory expectations. Companies such as We Seal work with food manufacturers to support packaging strategies that focus on functional performance while also addressing sustainability and compliance considerations. By developing sealing solutions that integrate efficiently with flexible packaging formats, We Seal helps businesses manage complexity and reduce unnecessary material use as EPR frameworks continue to evolve. WeSeal sealing solution designed for plastic and paper bags, helping manufacturers adapt packaging for EPR requirements.

How Does EPR Fit Into Broader Sustainability and Waste Reduction Goals?

EPR is closely linked to wider sustainability objectives, including waste reduction and improved resource efficiency. Packaging that supports food waste reduction can deliver environmental benefits that go beyond recycling alone. For example, packaging that helps maintain product quality after opening can reduce household food waste, lowering the environmental impact associated with producing and disposing of uneaten food. When combined with material-efficient packaging design, this approach supports the broader intent of EPR.

Why Is EPR Driving Long-Term Change in Packaging Strategy?

EPR represents a long-term shift rather than a short-term regulatory hurdle. As reporting requirements mature and fee structures develop, packaging decisions made today will continue to influence compliance costs and sustainability performance in the future. For food manufacturers and bakeries, this makes packaging strategy an increasingly important part of business planning. Working with experienced partners such as WeSeal to review sealing and closure solutions through an EPR lens can help businesses prepare for a regulatory environment where cost, performance, and sustainability are more closely linked than ever before.