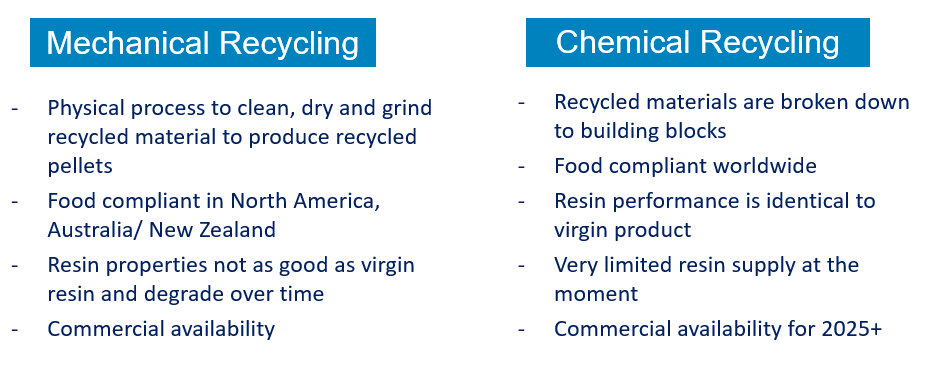

Mechanical vs. chemical vs. advanced recycling. What are the differences?

There are two main ways to produce recycled resins: via mechanical or advanced processes. Mechanical recycling involves a physical change in the recycled material without changing the polymer composition; and advanced recycling refers to processes where the recycled material is broken down to its building blocks. Some of these processes include pyrolysis or gasification technologies. Chemical recycling is a type of advanced recycling, with many people using these terms interchangeably.

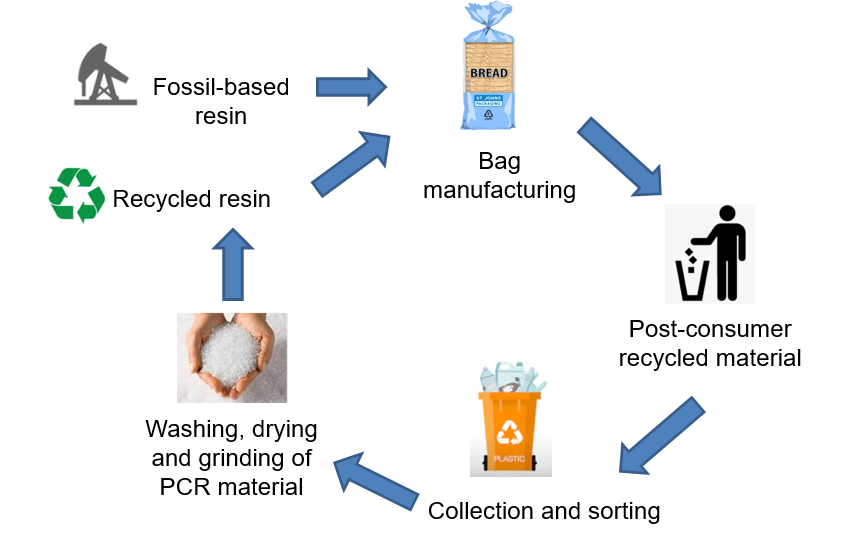

Mechanical recycling involves collecting plastic waste from a controlled polymer source, followed by washing, drying, grinding and melting to produce recycled pellets, which can then be used to make new packaging. Since heating polymers over and over again degrades their properties, the resulting pellets offer worse performance than virgin plastic and can only go through a limited number of recycling cycles. Colors and contaminants might not be necessarily removed in the process and this creates issues when trying to incorporate mechanically recycled resins into packaging for food products. There are many suppliers of these types of resins worldwide (food and non-food grade), and as recycling rates improve, it is expected that supply will also increase to meet the increasing demand of such products.

Mechanical recycling process

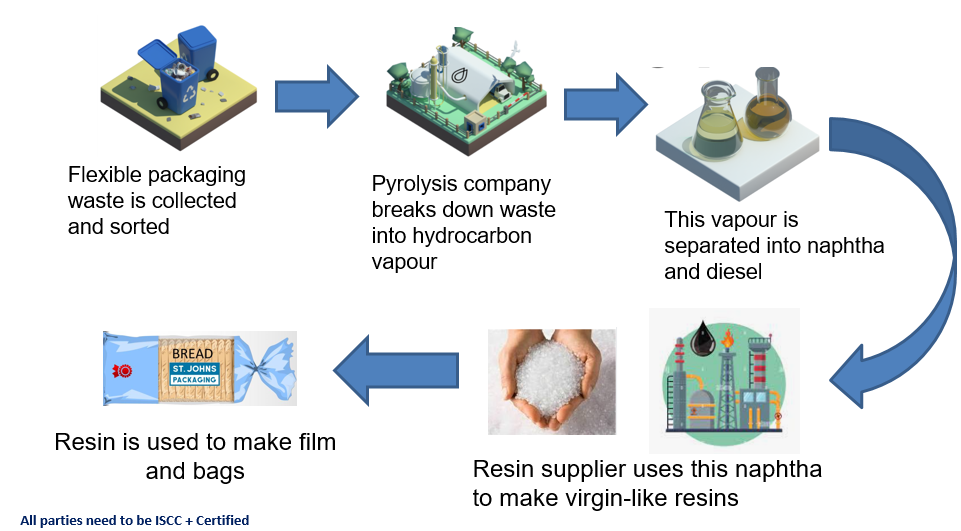

On the other hand, chemical recycling involves the collection of several types of soft plastics (usually polyolefin blends) mostly collected via store drop off programs, which are processed into oil via pyrolysis. Pyrolysis is a process where polymers are broken down into hydrocarbon vapour, back to their original building blocks, which can be used to produce new resins with identical properties to virgin resins. Some advantages of advanced recycling processes are that it can be repeated indefinitely and that all contaminants are removed, producing virgin-like materials, with the same properties and food compliance as traditional plastics. Unfortunately, current capacity is very limited, but it is expected to increase to larger commercial volumes in 2025 and beyond.

Chemical recycling process

The differences between the two recycling processes and the associated risks play a key role in the regulations for incorporation of recycled plastics in food contact applications in different parts of the world. In North America, the Food and Drug Administration (FDA) has established protocols to assess whether mechanical recycling processes are expected to produce recycled plastic of suitable purity for food-contact applications. The protocol considers the recycled waste origin and controls to ensure that food-grade plastic waste is used as incoming material, and it then looks at the cleaning efficiency of the recycling process through surrogate contaminant testing, also referred to as a challenge test. There are several FDA Letters of Non-Objection (LNO) issued to recyclers who provide recycled PET, PP and PE resins for food-contact applications for the North American market.

For the recycled resins produced via advanced or chemical processes, there are no issues with food compliance because the resins are of virgin-like quality and can be used in any application, be it for food or non-food contact.

Bread bags incorporating recycled content from both mechanical and advanced recycling processes have been commercially available since 2021, and with increasing supply of recycled resins there is a real opportunity to create more sustainable packaging in the bakery aisle. St. Johns Packaging is ready to help. More information available here:https://www.sjpack.com/pcr-bag-2/